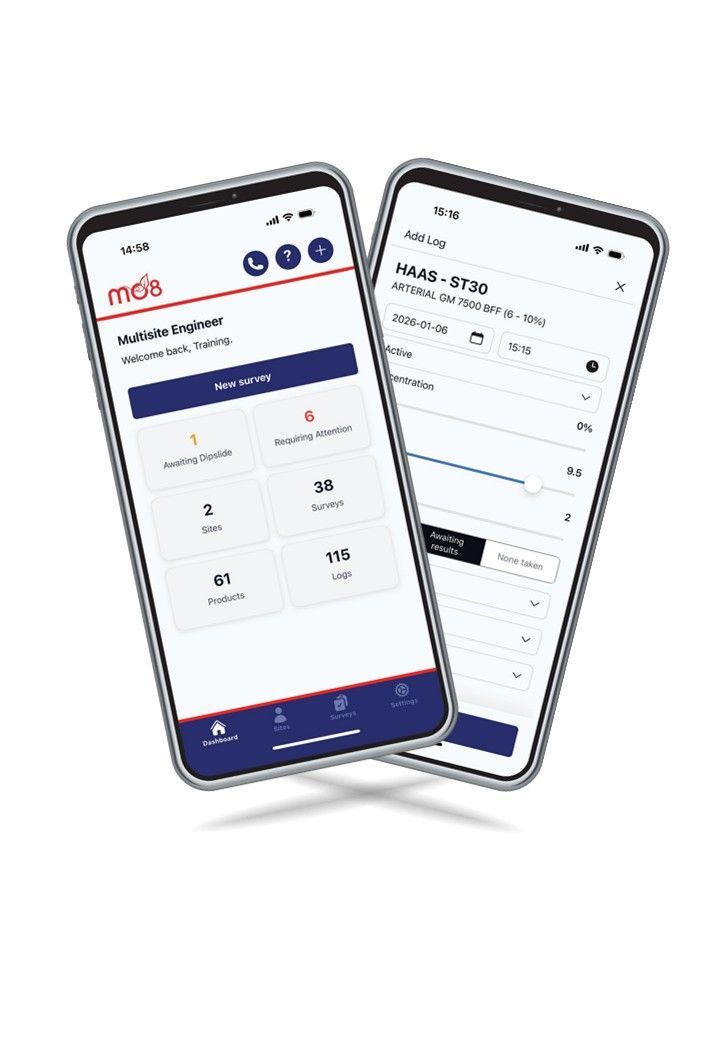

M-O-8 Coolant Monitoring App makes it simple to track and manage the health of your metalworking fluids. Designed for CNC machine users, the app allows you to quickly input key test results and view performance trends, helping you reduce downtime and improve coolant management.